![[Lone Sentry: WWII Tactical and Technical Trends]](../../pics/sentry120x69.jpg)

![[Lone Sentry: Photographs, Documents and Research on World War II]](../../pics/lonesentrylogo.jpg)

|

The following intelligence report on methods of clearing minefields was

published in Tactical and Technical Trends,

No. 33, September 9, 1943.

[DISCLAIMER: The following text is taken from the U.S. War Department

publication Tactical and Technical Trends. As with all wartime

intelligence information, data may be incomplete or inaccurate. No

attempt has been made to update or correct the text. Any views or

opinions expressed do not necessarily represent those of the website.]

|

|

METHODS OF CLEARING MINEFIELDS

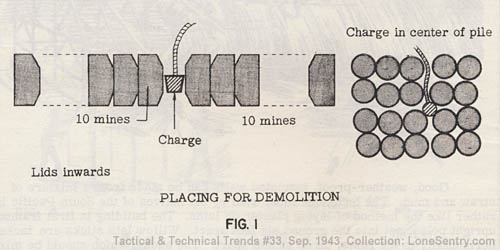

The importance which land mines has assumed in modern warfare has been discussed in Tactical and Technical Trends No. 27, p. 15, and No. 28, p 15 with reference to the laying of enemy minefields and the construction of enemy land mines. A knowledge of the different methods of clearing enemy minefields is as important as an understanding of the enemy tactics in laying the minefields. Information concerning the following methods for clearing minefields was taken from Allied sources covering operations in North Africa. In the first five methods the working party did not exceed one NCO and four men. a. Lifting and Placing in Dumps of 20 to 40 After locating, the earth was cleared around the mines and, without touching the igniter assembly,* the mines were lifted and carried a distance of approximately 30 yards depending on the size of the dump. They were either laid flat on the ground or on edge, with the top covers pointing inwards (see figure 1). The initiating charge was 1 primer, 1 detonator and 6 feet of safety fuze.

In the open country, clear of buildings, water mains or telegraph lines, a series of dumps of 30 to 40 mines were blown electrically using the truck storage battery as an exploder.

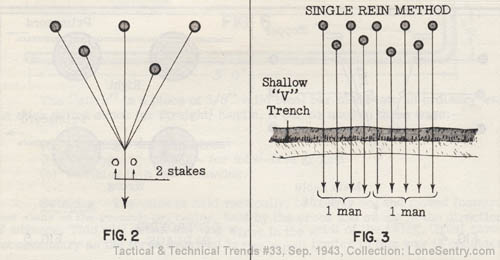

The rate of work was 60 mines per man per day; b. Cat-O-Nine Tails This was not very successful. Experiments proved that the method could only be used on very level ground and even then the mines cannot be drawn close enough (see figure 2) to insure that one charge will detonate them. It was found that they either had to be handpacked, or two or three separate charges were necessary to destroy each dump.

Rate of work (a) rough ground: no figure produced;

c. Single Rein Method This method was quite successful, even over rough ground. One man controls two or three and, over good ground, possibly four separate reins, which are made up of old signal cable (see figure 3). The mines are pulled into a shallow V-shaped trench from a distance of about 100 yards. The initiating charge is similar to that in method No. 1. It was found that blowing up in dumps of about 10 was the most convenient number.

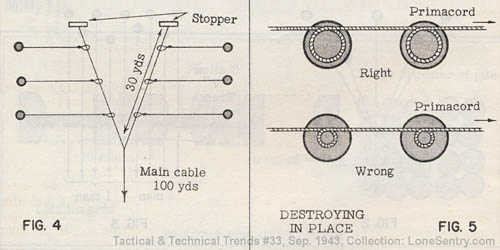

The rate of work: 30 mines per man per day; This method was not given fair trial over smooth ground. The rate of work in that type of ground would probably be 40 mines per man per day. d. Six in One This method was the quickest over smooth ground. It would undoubtedly have the disadvantages of other methods on rough ground. One man is capable of drawing in six mines at once with the assurance that they will be close together in the pit.

The main cable is 100 yards long and the two shorter lengths about 30 yards, each having a wooden stopper at the end (see figure 4). The six lengths that are attached to the mines are fastened by making a running loop on the 30 yard lengths. The wooden stopper prevents the loops from slipping off the 30 yard cable. A suitable arrangement is for the men to work in pairs and draw in 24 mines to each pit.

Initiating charge as in previous methods; e. Destroying in Place Primacord (instantaneous fuze) is ideal and does not require any subsidiary explosive. A loop on the top of each mine held in place by a stone is sufficient (see figure 5). One main point, however, is that the loop must be at least 3/4 the diameter of the mine, so that the pressure is towards the outer edge. Failures were reported if the loop was too small. f. Walking Stick Method The method of walking through a mined area using a walking stick (also known as the three-legged method) as described below has been used successfully (see figure 6).

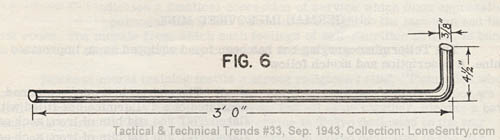

The "stick" is a piece of 3/8" mild steel bar made into an ordinary walking stick with a crook (or straight) handle. It can be used in three ways:- (a) Swinging - for trip wires (b) Testing or prodding - for mine-free ground (c) Swathing by a man crawling. Swinging - The stick is held vertically, or nearly so, and moved forward just clear of the ground; or, better, held by the crook and swung in the direction of advance. This will detect any trip wires in the orbit of the swing. Great care is not necessary as the force required to fire a pull igniter in this way is considerable. Testing - The stick is held at an angle of about 45 degrees and used to test the ground for one's next foot print. If the earth feels soft the stick is pushed into it and used as a probe. In walking through a minefield, the stick is used for swinging and testing in more or less one movement. If any obstruction is met with, the spot is NOT further investigated (unless on a mine reconnaissance), and another place is tested. Swathing - A man crawling uses the walking stick held horizontally and flat on the ground. He thus sweeps an arc of ground immediately to his front to detect 3-pronged igniters. The stick can also be used (held half-way down) as a "short arm" prodder. g. Clearing Antipersonnel Minefield From a recent report on clearing an enemy antipersonnel minefield the following points have been noted. (a) A careful search with a detector to insure 100 per cent clearance is necessary. (b) Engineers checked one field where they found two mines overlooked by the infantry who had already reported the area clear. *Of course any booby traps would first be neutralized, and it is thought that the igniter's are also neutralized. |

| Advertisement |